CASE STUDY - PINNACLE AWARD OF EXCELLENCE WINNER

MOYNIHAN TRAIN HALL

The James A. Farley Building, Moynihan Train Hall project, named after New York State Senator Daniel Patrick Moynihan, was a comprehensive plan to transform the iconic Pennsylvania Station and its surrounding buildings into a world–class transportation hub. The total renovation of 1.3 million square feet, ultimately expanding Penn Station’s entire floor space by more than 50 percent, which included the construction of a new 255,000 SF Moynihan Train Hall, waiting areas, and ticketing areas for the Long Island Railroad and Amtrak.

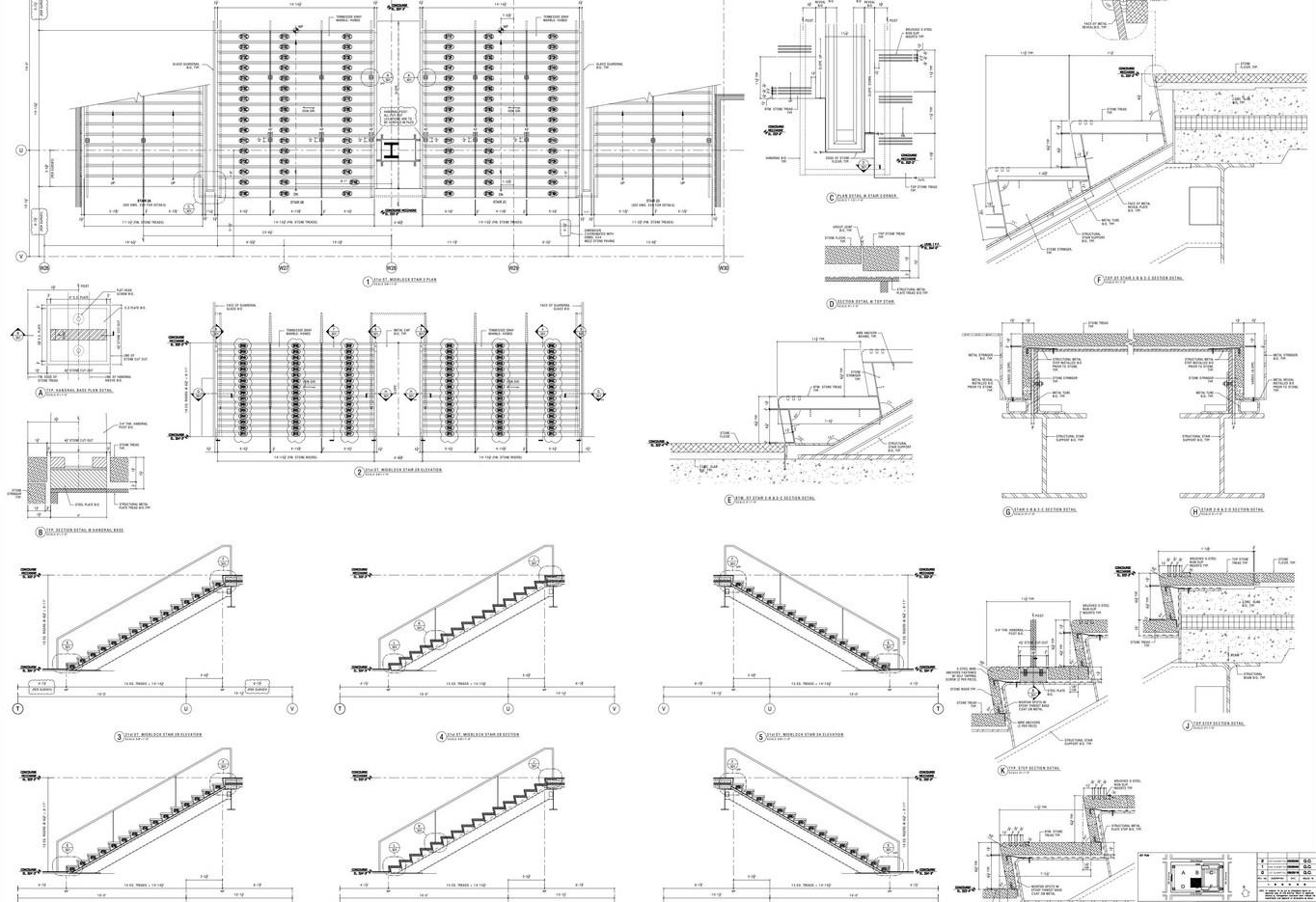

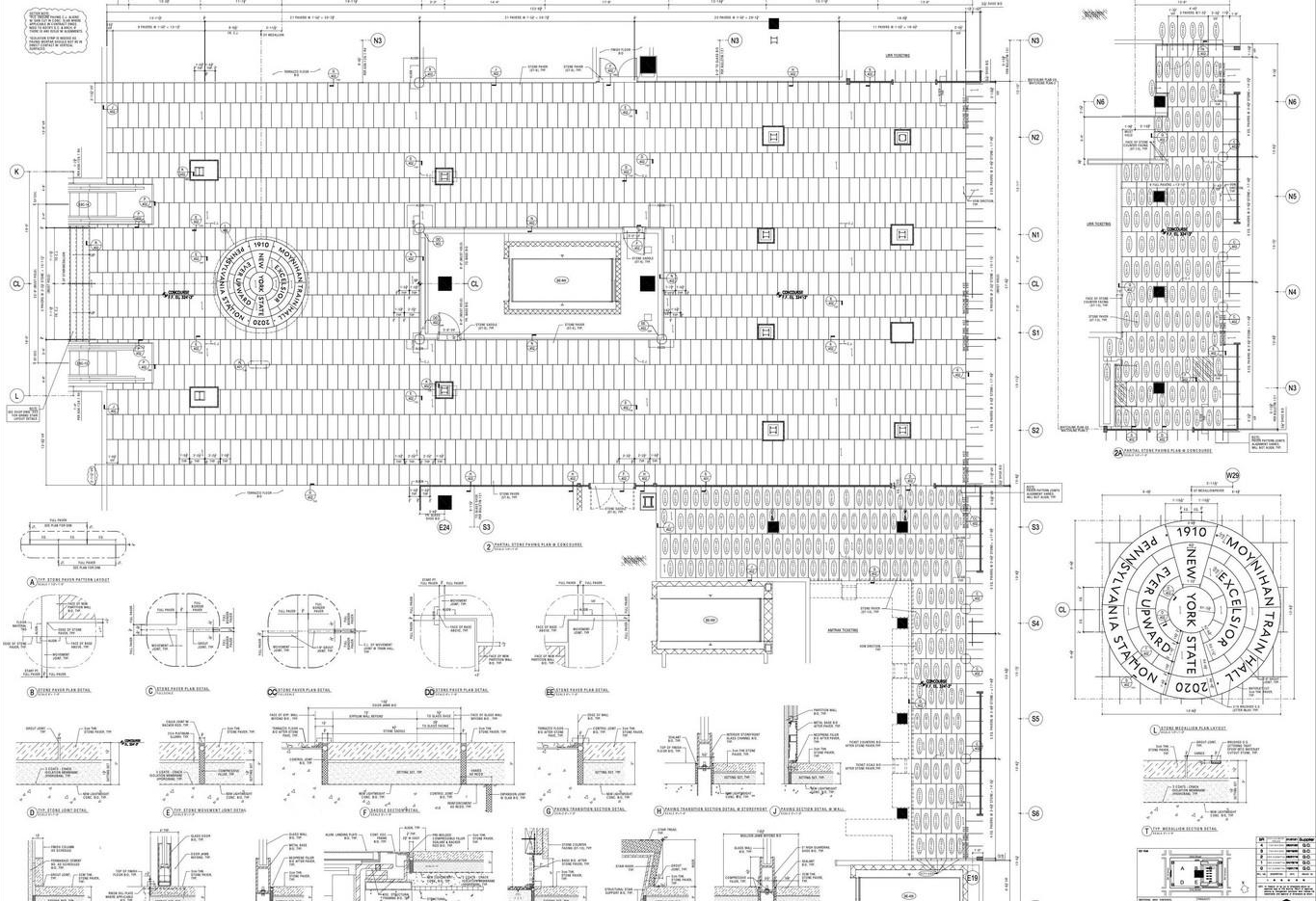

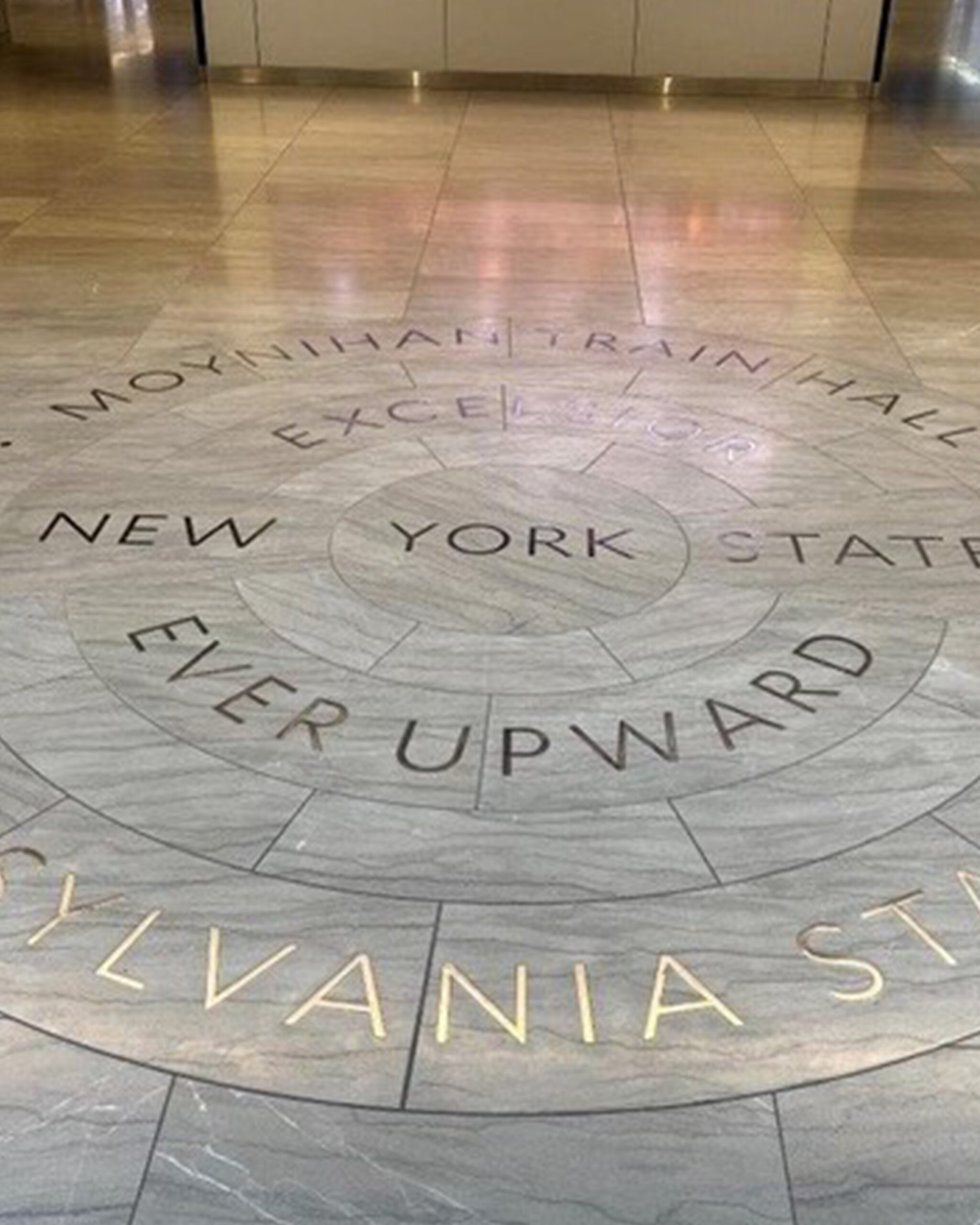

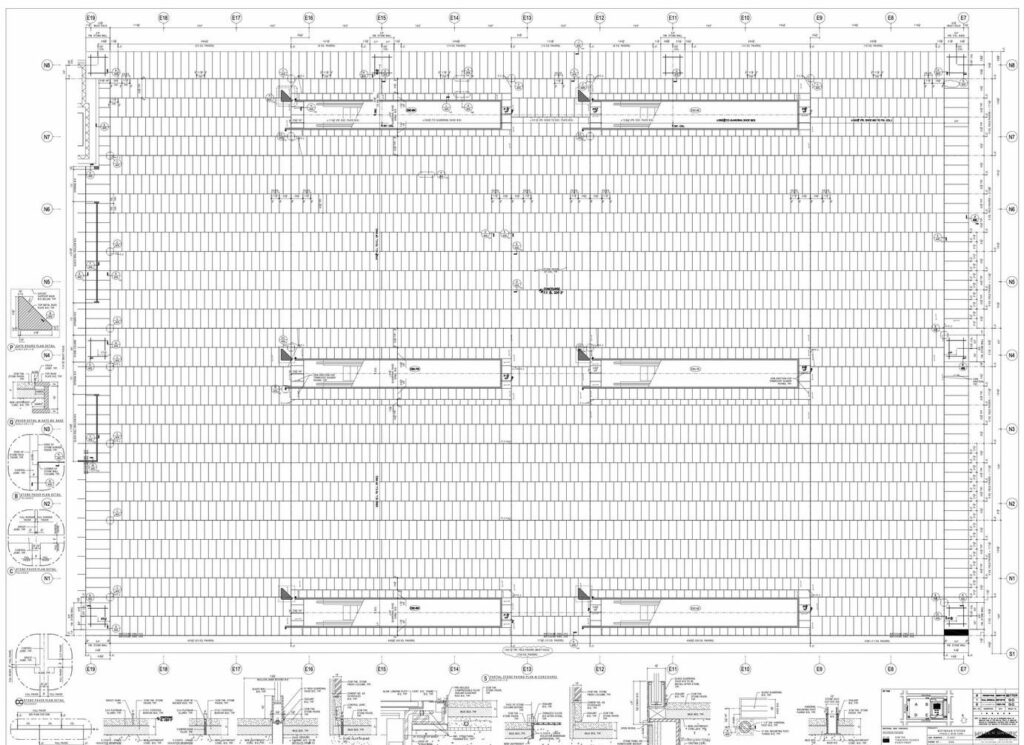

The project incorporates carefully selected stone materials and artwork that unify the entrances and concourses. The interior materials selected for the project were used for floors, walls, and soffits throughout the Train Hall. Grey marble is used in the Train Hall and in entrances at both 31st and 33rd streets in a honed finish for the floors and in a sandblasted finish for the walls. For LIRR and Amtrak ticketing, the beautiful white marble is a honed finish and was used for floors, walls, and soffits in those areas. The exterior stone was to match the existing of the Farley Post Office.

As we know, all projects come with challenges in and of themselves, and renovating a historic iconic building such as the Farley Building is no exception. Now imagine commencing with the project just before the onset of a global pandemic. New York State deemed the completion of the project as essential, with the goal of keeping The Moynihan project going and on schedule throughout the Pandemic. This meant that, not only were the factories and the fabrication shops to remain open under the most stringent safety measures, but also maintain a safe and healthy environment in the field for the stone mechanics and installers to work.

We had to work very closely with stone suppliers to secure additional equipment, personnel, and resources required to meet the block supply demands of the project. Their in–house personnel was supplemented by an outsourced quarrying team from another operation. We required bi–weekly reports and recovery projections to ensure the aggressive schedule requirements. All blocks were inspected prior to shipping. Blocks were then transported for slabbing and fabrication. Ownership required dry lays of all stone, reviewed for blending and to ensure conformity with the approved range. Due to the volume of square footage, the stone fabricators organized to have dry lays consisting of 6,000 sq. ft in one location to be viewed at a time. The white marble was used for the paving and claddings for the LIRR and AMTRAK areas to set it apart from the Train Hall. The slabs were prepared by the quarry and were cut to size in our Italian shop. All was presented for dry lay – some in person and some virtual.

It cannot be emphasized enough what a monumental endeavor the stone subcontractor did, with the collaboration of suppliers, fabricators, installers, and on-site installers, to maintain the project schedule while conforming with all the owners/architect’s demands, requirements, and changes. Moynihan opened to the public January 1, 2021, as scheduled despite all the hurdles and challenges, and went on to win the Pinnacle Award for the best project in 2022.